Chicken vent cutter

- Optimized cleaning

- Hygiene

- Simplified setting

- Efficient process

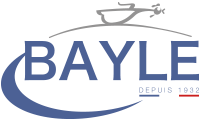

Description

The vent cutting of chicken is the first step of the automatic evisceration process.

Available in several configurations depending on your production capacity, the automatic vent cutter is designed for speed of 3 000/h to 8 000/h.

Made entirely in stainless steel, the chicken vent cutter is equipped with a hydraulic adjustment system that simplifies the machine settings between batches

The refined design of its frame allows an improvement of the cleanability, and thus improved hygiene by reducing the risk of bacterial contamination.

Chicken opening machine

- Cleanability

- Hygiene

- Optimal result

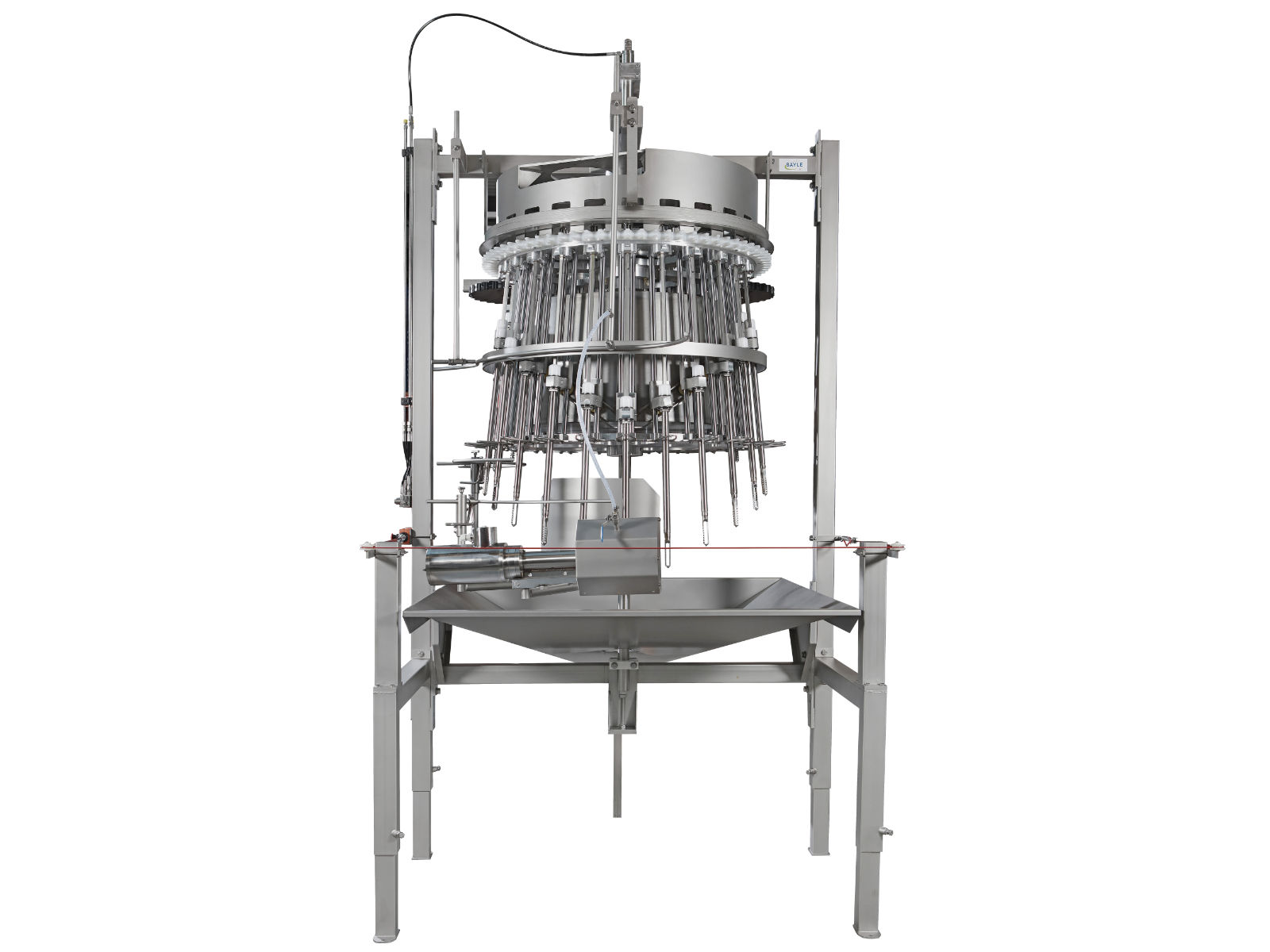

Description

The opening machine is the second step of the chicken evisceration process.

Slitting the abdomen of the chicken is necessary to ensure the smooth running of the following stages of the evisceration process, and in particular to improve the introduction of the eviscerating tool.

Made in stainless steel, the chicken opening machine integrates a hydraulic adjustment system that simplifies the machine settings between batches

The refined design of its frame allows the machine to be cleaned properly by making the central shaft easily accessible to the cleaning team.

The chicken opening machine is available in various configurations depending on your production capacity.

Automatic chicken eviscerator

- Optimized cleaning

- Optimum hygiene

- Efficient process

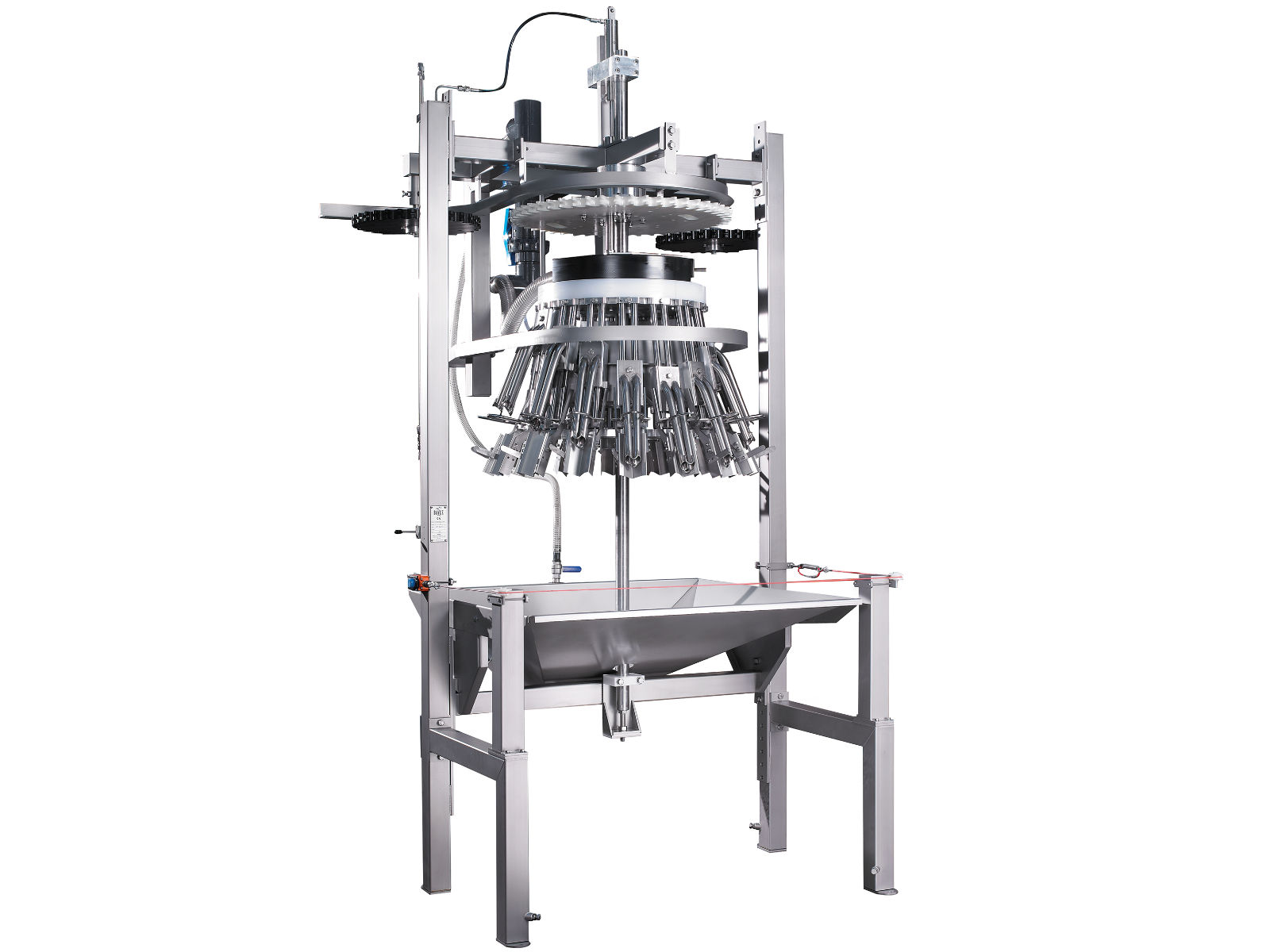

Description

The automatic chicken eviscerator is the third step of the evisceration process.

The eviscerator is a central stage in the poultry transformation processing and removes viscus (Intestine pack and giblets) from the chickens and place them on a transport belt in order to be treated afterwards.

Our engineering department has developed the automatic eviscerator to achieve an efficient and hygienic result. That is why, an evisceration tool specifically adapted to the anatomy of chickens has been developed. Our tool allows the removal of viscus without damaging the chicken in order to guarantee you a perfect finished product.

Hygiene is a key factor in poultry processing, so the eviscerator is equipped with a cleaning brush that ensures the hygiene of the evisceration tool between each chicken in order to minimize the risk of contamination

Made in stainless steel and equipped with a refined frame, all components of the automatic eviscerator are easily accessible for maximum cleanability and hygiene.

Supplied with a hydraulic adjustment system, the settings between the batches are simplified.

Available in several configurations for speed from 2 250/h to 8 000/H, our sale representatives will be able to advise you on the most suitable facilities for your production units.

Chicken cropper

- Optimized cleaning

- Hygiene

- Hydraulic settings

Description

The automatic chicken cropper DJB is the fourth step in the evisceration process.

Thanks to the development of a rotating tool that crosses the poultry, the neck is cleaned with the removal of the crop. In order to respect an impeccable hygiene, the tools are brushed and washed after each use.

Made in stainless steel, the refined design of the DJB allows easy access to all machine components and ensures proper cleanability.

The automatic chicken cropper is recommended for units between 3 000/h to 8 000/h. Depending on your expectations and needs, several configurations are available.

Chicken neck breaker

- Refined frame

- Stainless steel

Description

The chicken neck breaker is the fith step of the automatic evisceration process.

The neck breaking also called neck opening machine will remove the neck by breaking it.

Made in stainless steel, the neck breaker is designed with the refined frame that ensures a good cleanability of all the machine components to minimize the risk of bacterial contamination.

Available in several configurations for speeds between 3 000/h to 8 000/H, our sales representative will advise you how to adapt the equipment to your needs

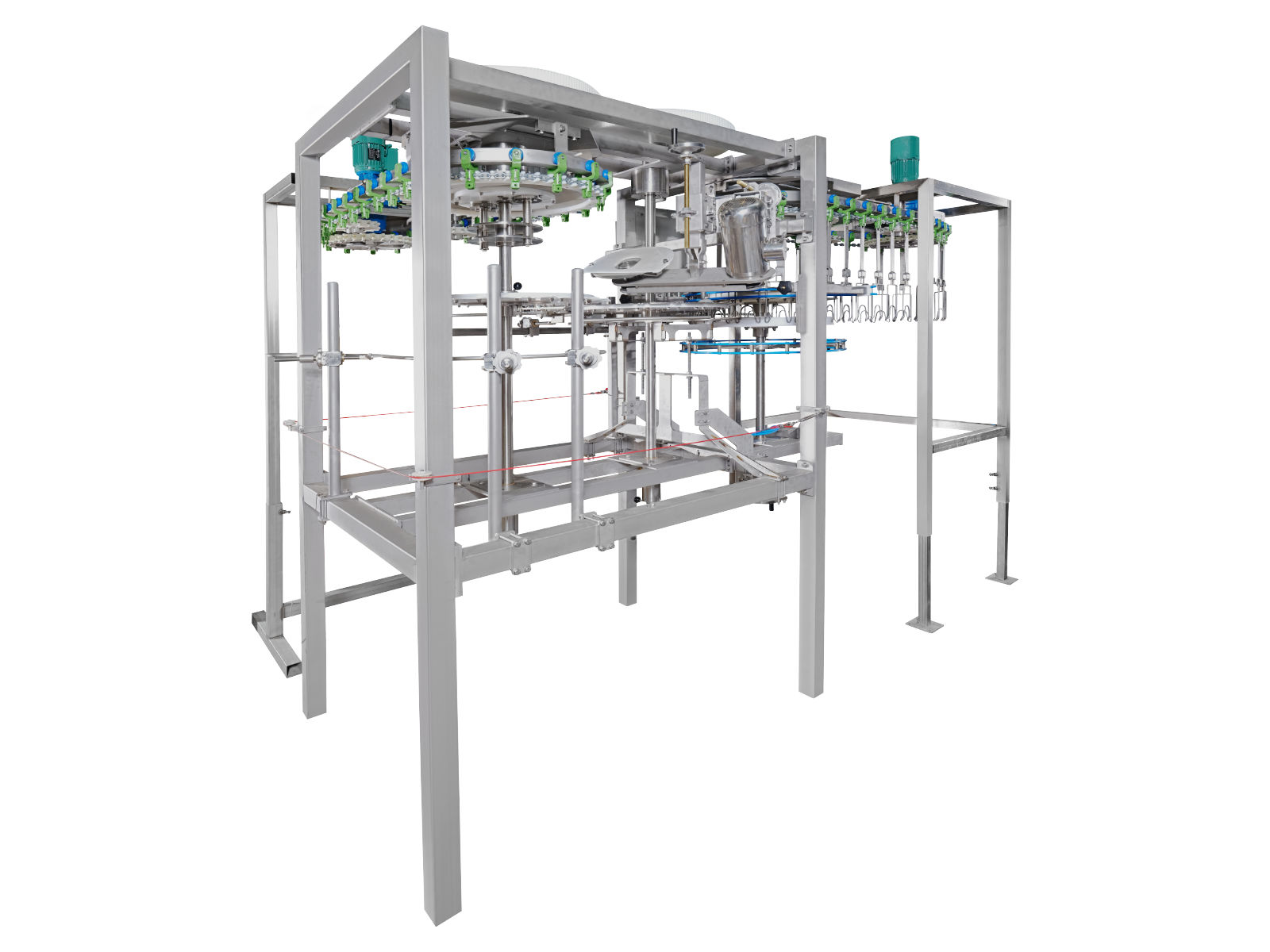

Chicken inside/outside washer

- Complete washing of poultry

- Optimized hygiene

Description

The inside/outside washer is the second to last step of the automatic evisceration process.

Designed to improve hygiene in poultry the slaughterhouse, the LIEP will wash the inside and outside of poultry after the evisceration process in order to obtain perfectly clean products.

Made in stainless steel, the LIEP is equipped with a hydraulic adjustment system that allows the machine to be adjusted between the different batches.

Available in several configurations to suit your needs according to your available space, our internal/external washer is recommended for units from 4 500/h to 8 000/h.

Final control

- Optimized cleaning

- Vacuum pump system

- Efficient process

Description

The final control is the ultimate step of the chicken automatic evisceration process.

This step consists of sucking the inside of the chicken to remove the lungs. The final control works with a vacuum pump suction system.

Made in stainless steel and designed with a refined frame, the final control is easily cleanable and the team can access all components for perfect hygiene of the equipment.

Available in several configurations the final control is recommended for units from 4 500/h to 8 000/h.

A vacuum pump installation is required for the proper operation of this equipment

Automatic transfer TRA

- Transfer on conveyor

- Several configurations available

Description

The automatic transfer TRA is an automated transfer system on conveyor for poultry. Thanks to TRA the chickens are automatically transferred from the slaughtering area to the evisceration area.

The automatic transfer is available in several configurations to suit your needs. the pitch is adjustable according to the type of poultry to be transferred. The poultry is transferred in long feet/short feet using an integrated saw.

Made in stainless steel, the TRA easily integrates on your conveyor lines.

This system can be placed at different locations on the slaughtering line to meet your automation needs. The automatic transfer of chickens from the evisceration line to the chilling area is also possible with this equipment.

Do you want to know more about it?

Contact our sales team

Our sales department is at our disposal to answer your questions. We have an agents network around the world, so do not hesitate to contact them to speak of your project.